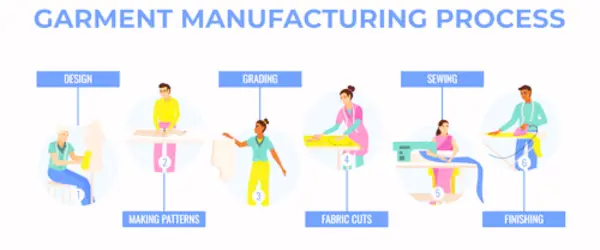

Discover the detailed Garment Production Process from design to delivery. Learn how quality apparel is crafted step-by-step.

The journey of your favorite t-shirt, comfy jeans, or stylish dress is a fascinating one. It all starts with a spark of creativity and culminates in a finished product ready to be worn. But what happens in between? This blog post will delve into the intricate world of garment production, exploring each key stage from design concept to the final product.

Design and Development

The magic begins with a designer’s vision. This isn’t just about sketching a pretty picture. Fashion designers translate trends, consumer preferences, and brand identity into a cohesive collection.

They experiment with fabrics, silhouettes, and details, meticulously considering drape, movement, and wearability. Sketches come to life through technical drawings that specify seam lines, closures, and construction methods. These drawings serve as the blueprint for the garment’s functionality and form.

Fabric Selection and Sourcing

The heart of any garment lies in its fabric. Fabric selection involves considering a multitude of factors. Material weight and drape significantly impact the garment’s silhouette. Breathability determines comfort, especially for activewear. Durability is crucial for items that will see a lot of wear and tear. Manufacturers work closely with fabric suppliers to source the right material at the best price point. Sustainability is a growing concern, and many manufacturers prioritize eco-friendly fabrics like organic cotton or recycled polyester.

Pattern Making and Grading

Once the design and fabric are finalized, it’s time to translate the vision into a blueprint. Patternmakers, the unsung heroes of garment production, meticulously craft the garment’s template, ensuring each piece fits together perfectly.

They use specialized software or traditional paper drafting techniques to create precise patterns that account for seam allowances and fabric grain. Grading involves creating size variations of the base pattern to cater to different body types. A skilled pattern grader ensures a proportional size increase across all dimensions, maintaining the garment’s design integrity throughout the size range.

Spreading and Cutting

The fabric is carefully laid out in layers, a process called spreading. Spreaders use their expertise to maximize fabric utilization and minimize waste. This can involve complex layouts that take into account pattern shapes and fabric direction. Using the patterns as guides, the fabric is then precisely cut using sharp blades or laser cutters, depending on the production facility’s technology.

Laser cutting offers clean edges and minimal fraying, while traditional blade cutting requires additional finishing steps.

Assembly and Sewing

The garment pieces, now cut and ready, enter the assembly line. Skilled sewing machine operators meticulously stitch the pieces together, following the designated seams and construction techniques. Different stitch types are used for various purposes. Strong seams like the backstitch are used for areas that experience stress, while decorative stitches can add visual interest.

Experienced sewers ensure consistent stitch quality and proper seam allowances throughout the garment.

Finishing and Quality Control

The garment takes shape, but it’s not quite ready yet. Finishing touches elevate the garment from a collection of pieces to a cohesive whole. Trims like ribbons, piping, or lace can add decorative elements. Buttons, zippers, and other closures are applied for functionality. Washes can be used to soften the fabric, create a vintage look, or enhance durability.

Throughout the process, rigorous quality checks ensure the garments meet the desired standards and are free of defects. Inspectors examine seams, stitching, hardware placement, and overall finish, ensuring each garment is ready to meet customer expectations.

Packaging and Distribution

The finished garments are carefully inspected one last time, then folded and packed according to retailer specifications. This might involve individual packaging with hang tags and labels, or bulk packaging for further distribution. They are then shipped to warehouses, distribution centers, or directly to retailers, finally reaching the shelves ready to be discovered by you!

This is a simplified overview of the garment production process. The specifics may vary depending on the garment type, production volume, and technological advancements. But one thing remains constant – the dedication and expertise of countless individuals who transform a creative vision into the clothing we love to wear.

Conclusion: The Future of Garment Production

The garment production process is constantly evolving. Automation is playing an increasingly important role, with computer-aided design (CAD) software streamlining the design and pattern-making stages. Laser cutting offers greater precision and efficiency, while robotics can automate some sewing tasks. However, skilled workers remain irreplaceable, ensuring quality control and the intricate craftsmanship that elevates garments from mass-produced to truly special pieces.

The future of garment production is likely to focus on sustainability. Consumers are demanding more eco-friendly practices, and manufacturers are exploring innovative solutions. This includes using recycled materials, organic fabrics, and water-efficient dyeing processes. Additionally, on-demand manufacturing is gaining traction, reducing waste by producing garments only when there’s a confirmed order.

The garment production process is a fascinating blend of creativity, technical expertise, and skilled labor. As the industry continues to evolve, one thing is certain: the journey from sketch to shelf will remain a testament to human ingenuity and our constant pursuit of style and comfort.

You must be logged in to post a comment.